Cutting and Welding

Welding PVC Parts – The Ideal Solution for Your Needs!

PVC Folie Part Welding

Why Choose PVC Folie Part Welding?

How the PVC Part Welding Process Works

PVC part welding is a process that uses heat to fuse two or more pieces of PVC material together. This creates a strong and durable bond.

Looking for a Precise and Efficient Way to Cut Foam and Other Materials?

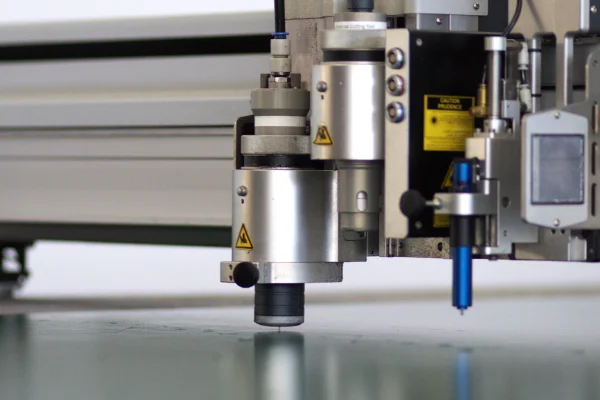

Consider our plotter cutting services! A plotter is a machine that uses a sharp blade to cut any shape from various materials, such as:

Plotter cutting is much faster and more precise than traditional methods like hand-cutting or die-cutting. Additionally, our experienced operators minimize waste, reducing production costs.

Quality Guarantee

We guarantee high quality workmanship and fast turnaround times. Our modern machinery and experienced workforce are capable of handling even the most demanding tasks.

Do You Need Sewing Support?

Looking for a partner to help you realize your project?